Internet Explorer is not supported. Please upgrade to a more modern browser.

EQiblyzew

MemberFeed

About

Registered

22 Jan 2025, 22:19

Last Seen

15 Feb 2025, 14:39

Latest Posts

6 months ago

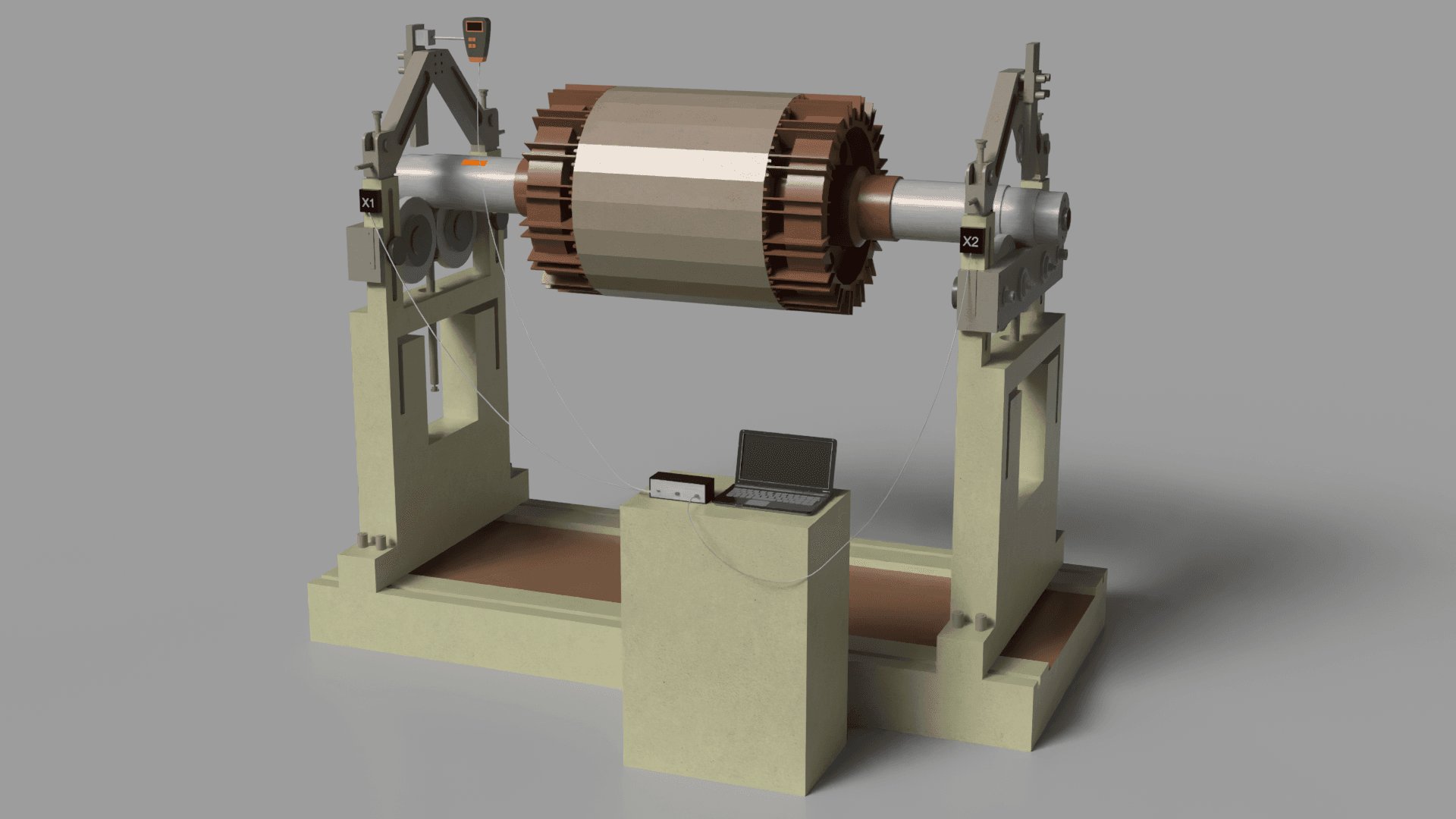

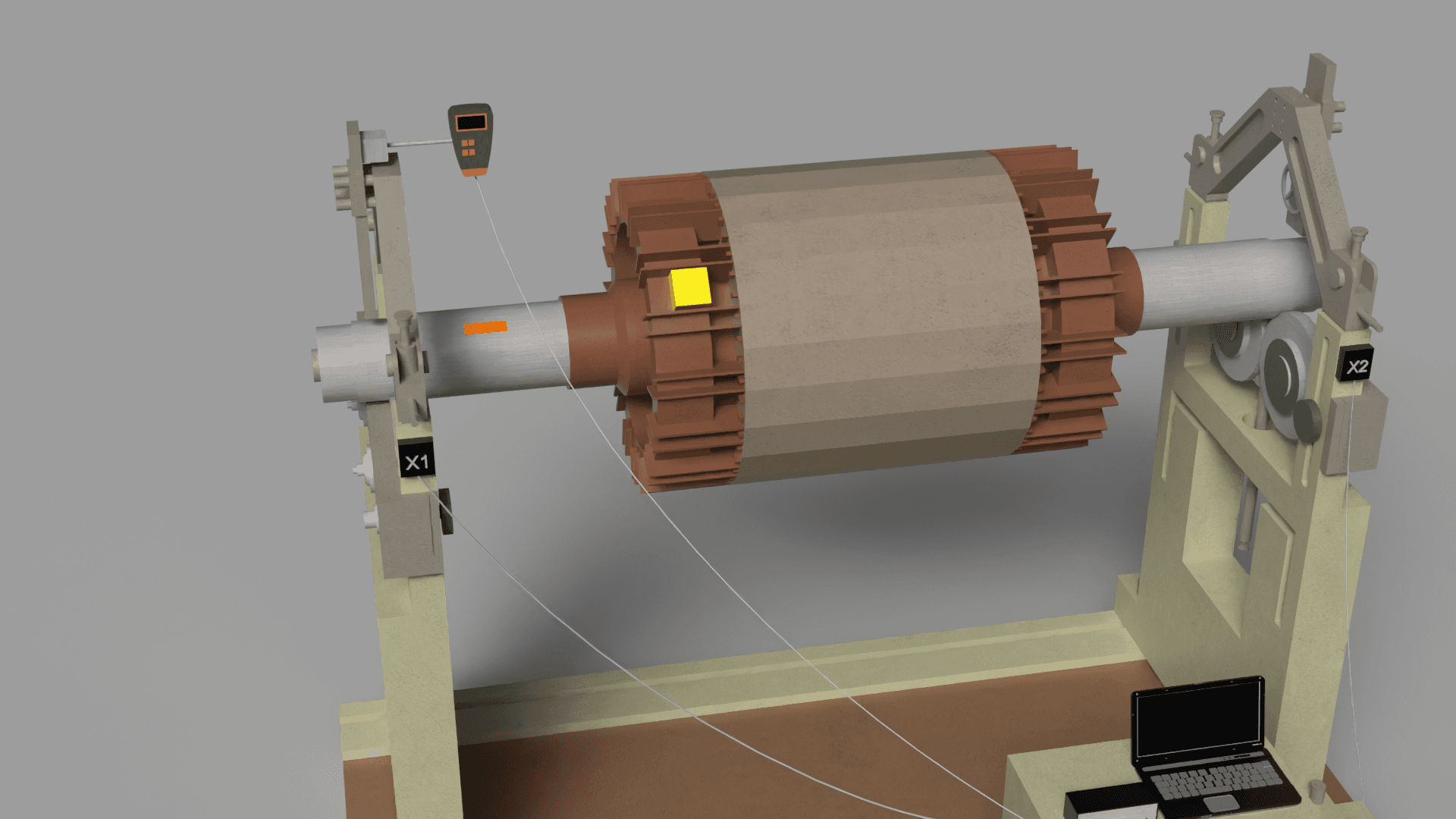

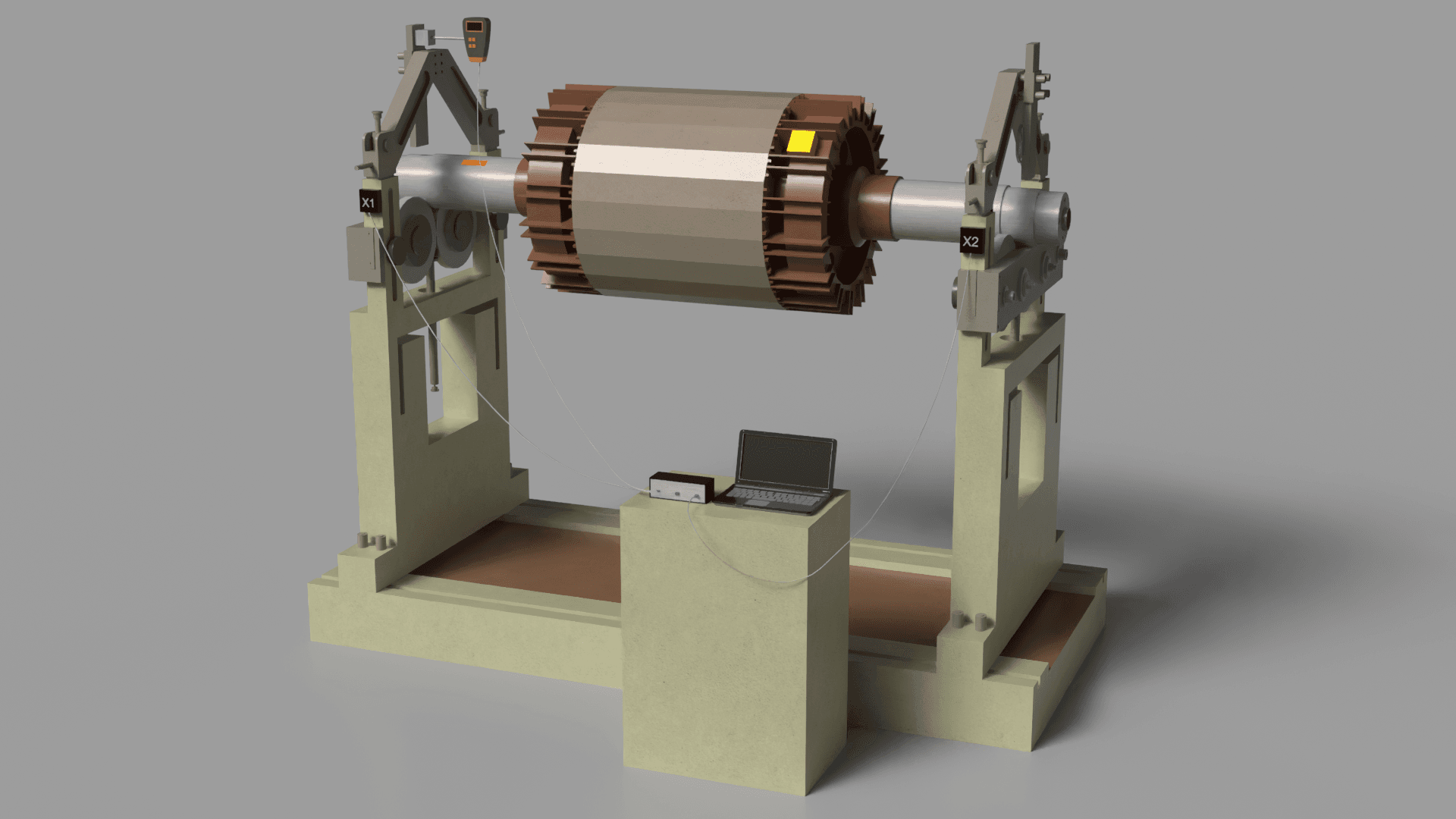

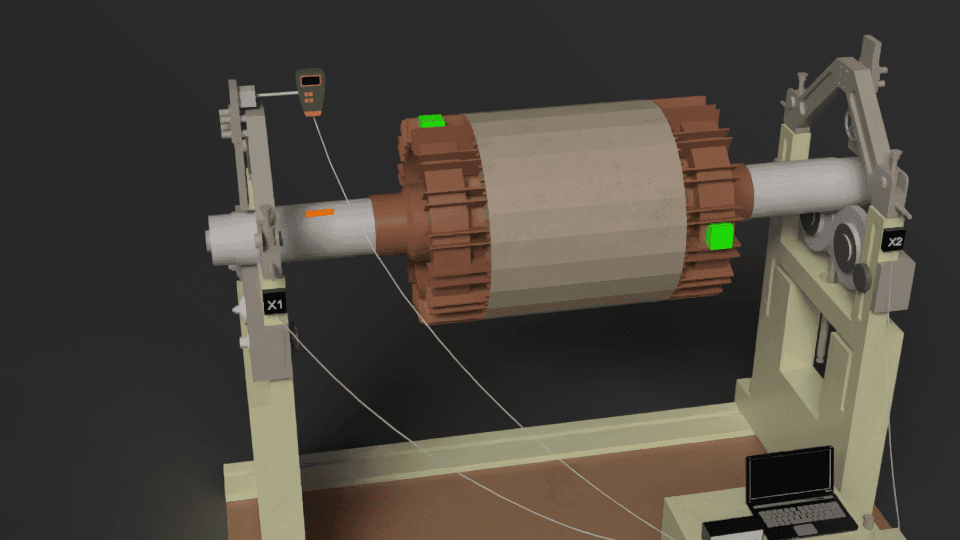

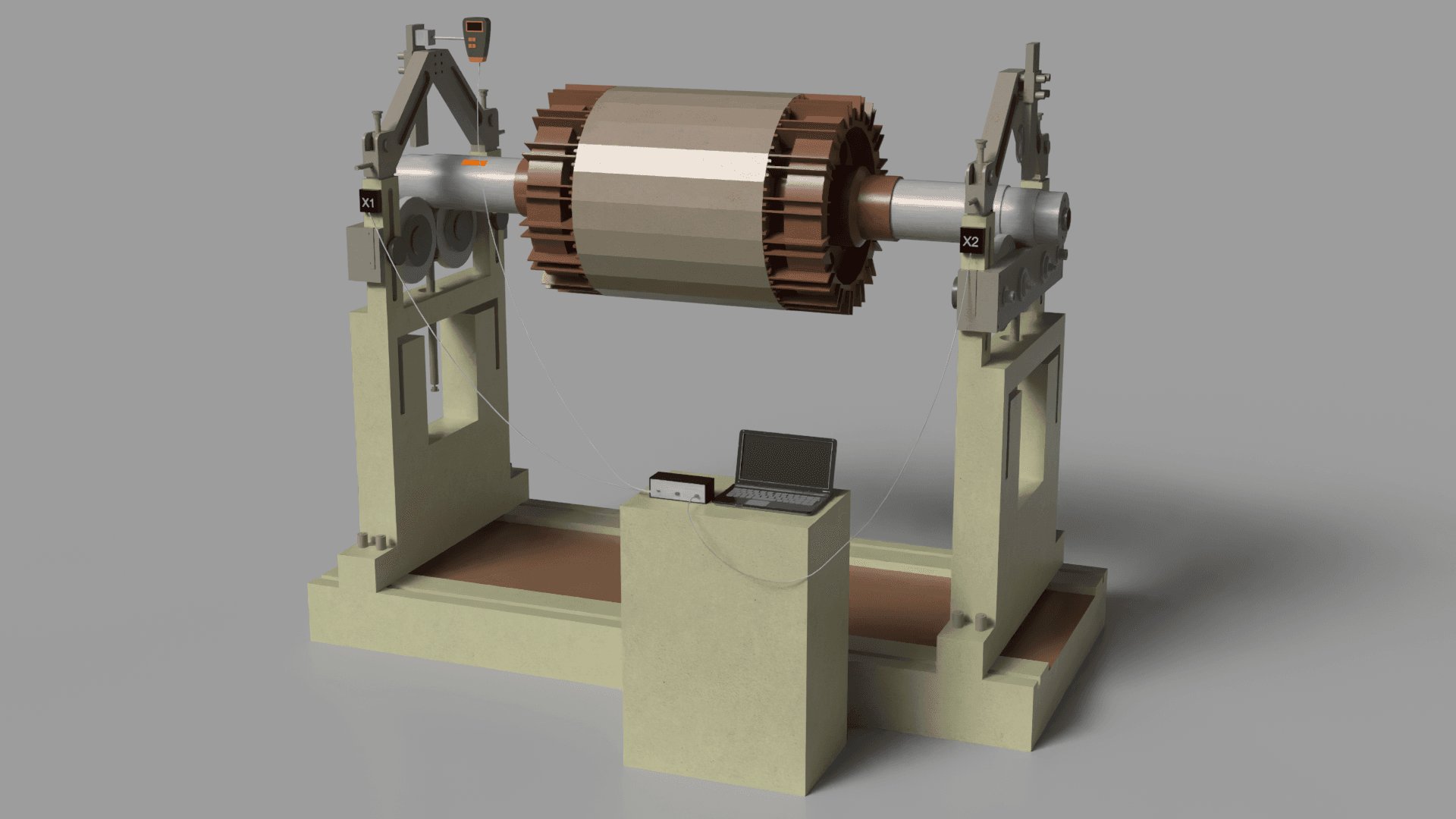

Rolling mill balancing

Rolling mill balancing

15 Feb 2025, 14:39

Rolling mill balancing

15 Feb 2025, 14:39Balanset-1A: Balancing made uncomplicated and widespread

Rotor imbalance is a common cause of machinery failures, second only to bearing wear in frequency. Imbalance can arise from temperature fluctuations . While replacing bearings is often the only solution for wear, rotor imbalance can be corrected on-site through balancing, a procedure that is part of vibration adjustment .

Traditionally, this process necessitated complex and expensive vibration analyzers operated by experienced specialists. However, Vibromera has developed the Balanset-1A, a instrument designed to simplify on-site rotor balancing, making it accessible even to personnel with minimal training, including maintenance services .

The core philosophy of Balanset-1A is simple: rotor balancing should be achievable on-site, by anyone, without extensive knowledge and without exorbitant costs. Instead of being a secondary function of a complex vibration analyzer, balancing is the primary focus of Balanset-1A. While it includes a fundamental built-in vibration signal analyzer to detect imbalance and other basic defects, its main goal is simplified and convenient balancing.

This focus provides significant advantages. Balanset-1A is designed for simplicity , allowing users to quickly and effectively eliminate rotor imbalance. This user-friendliness enables maintenance personnel to take proactive measures in maintaining equipment functionality.

Additionally, Vibromera has made the Balanset-1A exceptionally affordable. Priced at just €1751 , it offers excellent value for money, especially considering the complete package.

The complete package includes:

- Measurement unit: The heart of the system, analyzing sensor data and guiding the balancing process.

- Two vibration sensors: They with high precision capture the rotor's vibrational characteristics.

- Optical sensor (laser tachometer): Used for measuring rotational speed and phase determination .

- Magnetic stand: Provides stable and versatile mounting of sensors.

- Electronic scales: Necessary for accurate weight adjustment during balancing.

- Software: User-friendly software accompanies the balancing process and provides detailed reports.

- Transport case: Ensures secure and convenient transportation of the entire system.

With this complete package, users have everything needed to perform both single-plane and two-plane balancing right out of the box . This eliminates the need to purchase extra parts and simplifies the setup process.

In conclusion, the Balanset-1A represents a significant step forward in making rotor balancing accessible . With an emphasis on ease of use and offering a complete and cost-effective solution, Vibromera empowers service crews to effectively eliminate rotor imbalance, ultimately enhancing durability and reducing downtime. The Balanset-1A proves that with the necessary tools, even challenging maintenance tasks can be made simple and accessible to all .

Instagram: https://www.instagram.com/vibromera_ou/ Youtube : https://youtu.be/guA6XJ-ArZM?si=vmkuX7RILzKBl0zL Our website about Balancing of mining equipment Machinio: https://www.machinio.com/listings/98380186-portable-balancer-vibration-analyzer-balanset-1a-full-kit-in-portugal Facebook: https://www.facebook.com/marketplace/item/350151228150722 https://martinhwky25814.angelinsblog.com/25826916/vibromera-leading-in-balancing-and-vibration-analysis

7 months ago

How to eliminate asynchronous motor vibration?

How to eliminate asynchronous motor vibration?

27 Jan 2025, 19:50

How to eliminate asynchronous motor vibration?

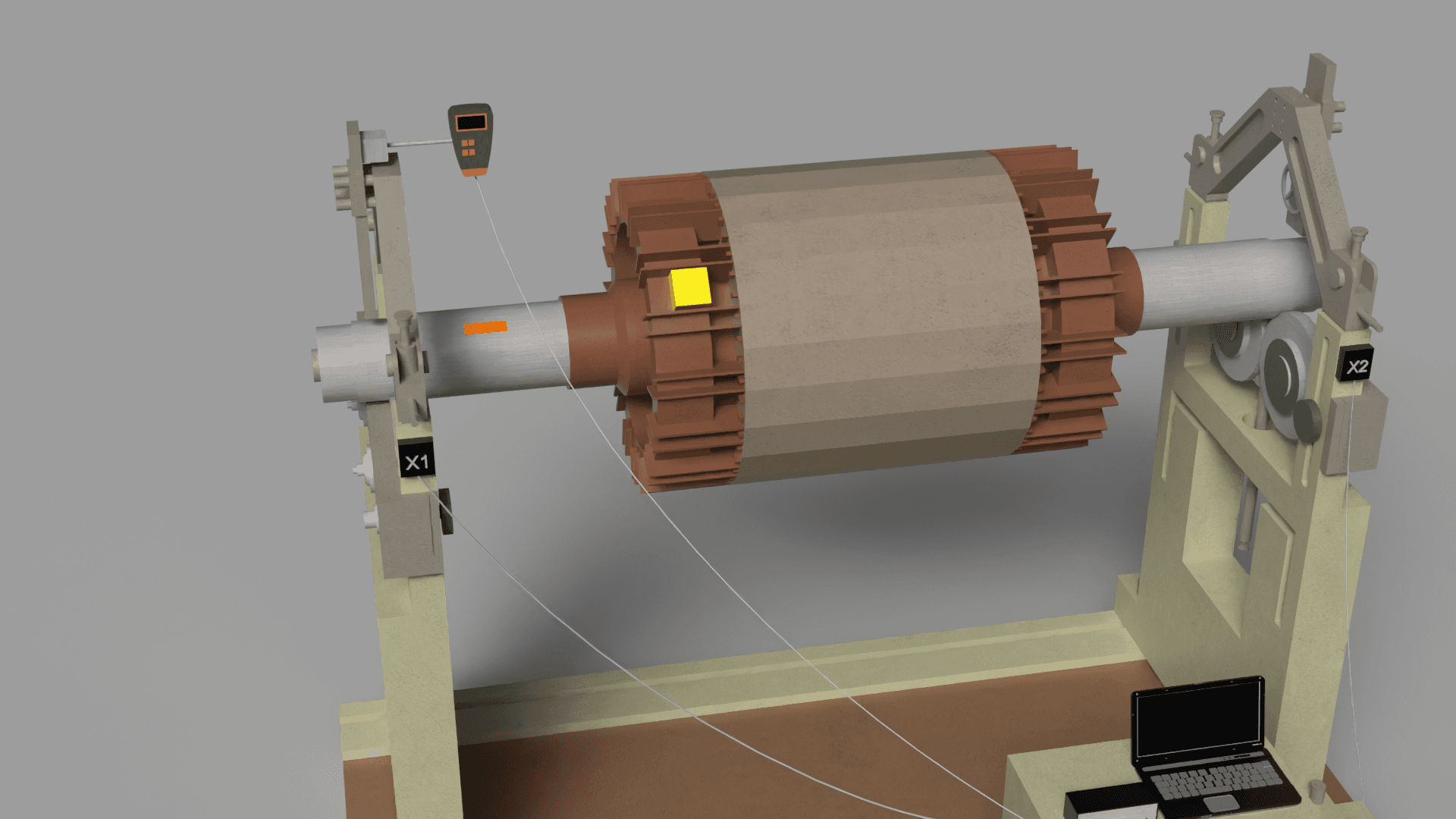

27 Jan 2025, 19:50Detailed Rotor Balancing Process

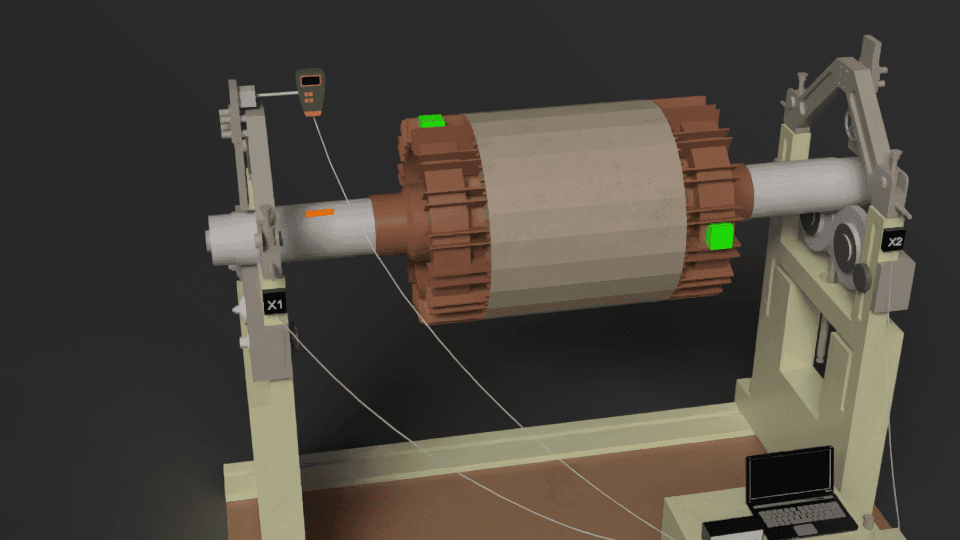

Getting the Equipment Ready

- vibration sensors, optical speed sensor, magnetic base, software package, and included accessories.

- Connect the device to your PC using the USB interface and confirm the software installation.

Sensor Installation

- Fix the accelerometers securely to the machine's structure in locations where vibrations are most prominent, ideally near the bearings.

- Direct the laser speed sensor towards the rotor and affix reflective tape to the rotor surface to facilitate phase angle measurement.

Launching the Software

- Open the Balanset application on your PC.

- Configure the software for either single-plane or two-plane balancing, based on the rotor's characteristics and the desired outcome.

Initial Vibration Measurement

- Run the rotor up to its operating speed.

- The program will record the vibration amplitude, rpm, and phase, providing a baseline measurement of the existing imbalance.

Mounting the Test Weight

- Halt the rotation and mount a test weight at a designated position on the rotor, with the weight's value entered into the software (usually in grams).

- Restart the rotor, and the software will record the changes in vibration level and phase angle.

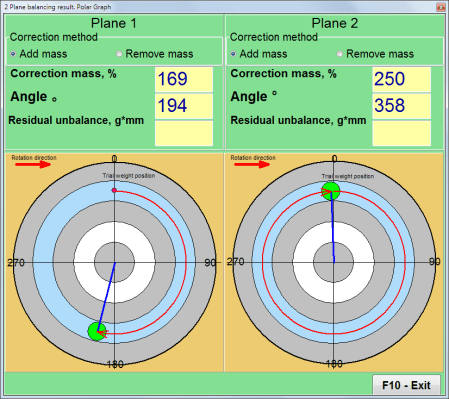

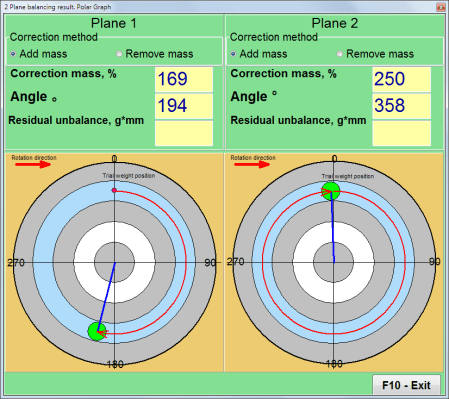

Determining the Corrective Mass

- The software uses the measured values to automatically compute the necessary compensating weight's magnitude and placement angle.

- The calculated values are presented on-screen in both numerical and graphical formats.

Mounting the Compensating Weight

- Mount the calculated corrective weight onto the rotor at the specified location and angle.

- If necessary, perform intermediate checks to verify that the imbalance is being reduced.

Final Check and Balance Confirmation

- With the compensating weight attached, operate the rotor and assess the level of any residual vibration.

- If the measured vibration falls within the tolerance defined by ISO 1940, the balancing process is considered successful.

- If the vibration level remains high, repeat the process with further weight adjustments.

Report Generation

- All balancing results are logged and archived within the software, from which you can produce a printable report summarizing the vibration levels, compensating weight, and its installation position.

Concluding Steps and Verification

- Verify the secure attachment of all balancing weights and measurement sensors.

- Confirm that the rotor spins freely and quietly, without any unusual sounds or vibrations.

- If the rotor operates within a larger assembly, check the functionality and interplay of all interconnected parts.

By implementing this method, you can effectively eliminate imbalance, reduce vibration levels, and increase the lifespan of the machinery.

Instagram: https://www.instagram.com/vibromera_ou/ Youtube : https://youtu.be/guA6XJ-ArZM?si=vmkuX7RILzKBl0zL Our website about Tuned mass damper Machinio: https://www.machinio.com/listings/98380186-portable-balancer-vibration-analyzer-balanset-1a-full-kit-in-portugal Facebook: https://www.facebook.com/marketplace/item/350151228150722

7 months ago

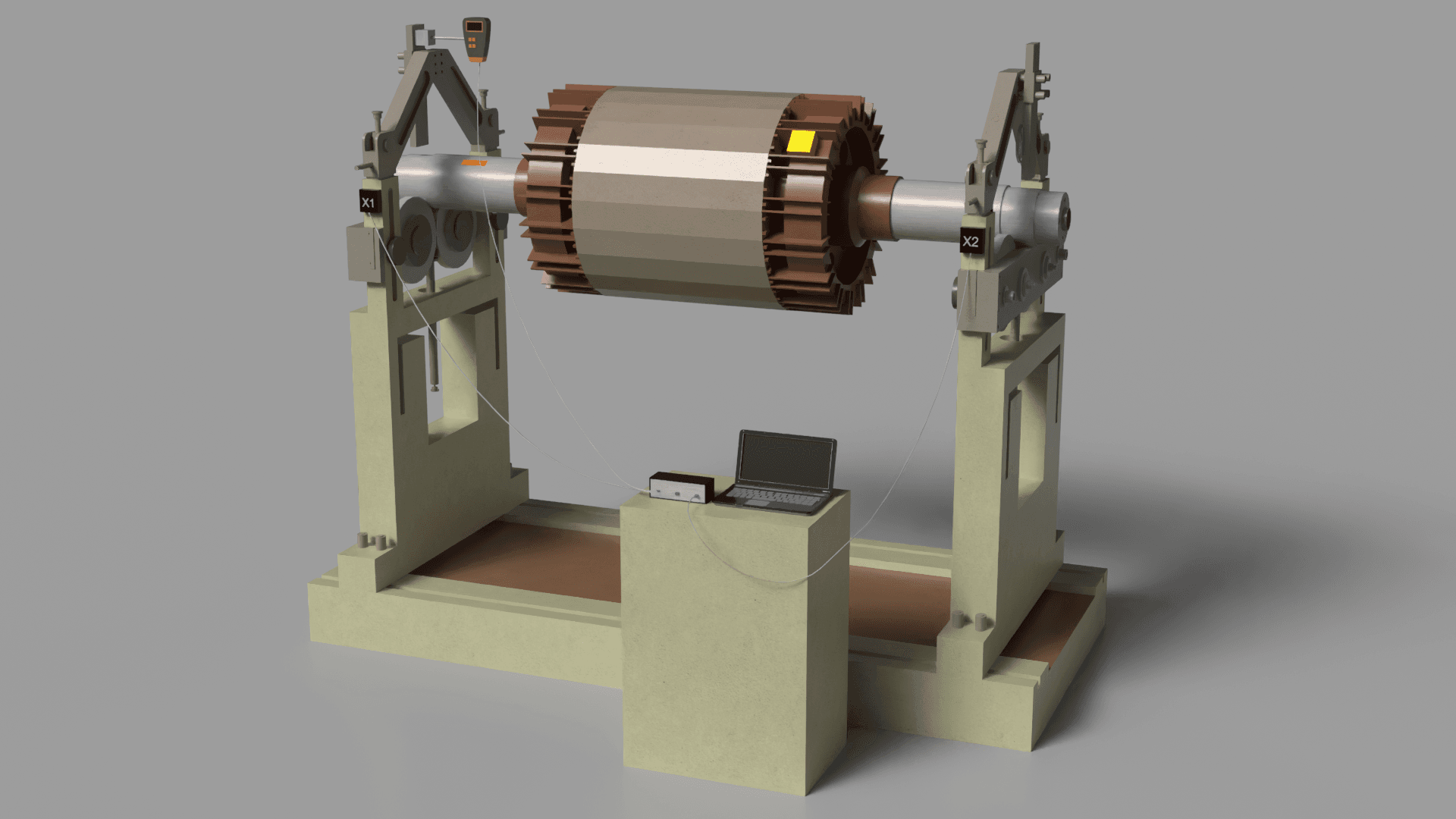

Upgrade your toolkit with Balanset-1A

Upgrade your toolkit with Balanset-1A

22 Jan 2025, 22:19

Upgrade your toolkit with Balanset-1A

22 Jan 2025, 22:19with the Balanset-1A Device

Getting the Equipment Ready

- vibration sensors, optical speed sensor, magnetic base, software package, and included accessories.

- Establish a USB connection between the instrument and the computer, ensuring the software is set up properly.

Setting Up the Sensors

- Mount the vibration transducers securely on the machine's housing where vibrations are most pronounced, typically near the bearings.

- Position the laser tachometer (phase angle sensor) so that it is aimed at the rotor. Attach reflective tape to the rotor for accurate phase angle reading.

Launching the Software

- Open the Balanset application on your PC.

- Choose the correct balancing method (single or two-plane) according to the rotor configuration and the balancing task.

- Bring the rotor to its normal operating rotational frequency.

- The program will record the vibration amplitude, rpm, and phase, providing a baseline measurement of the existing imbalance.

Trial Weight Installation

- Stop the rotor and attach a trial weight at a specific location on the rotor. The weight's mass can be specified within the software (e.g., in grams).

- Resume rotor operation, and the program will capture the resulting changes in vibration amplitude and phase.

Computing the Compensating Weight

- The software uses the measured values to automatically compute the necessary compensating weight's magnitude and placement angle.

- The calculated values are presented on-screen in both numerical and graphical formats.

Attaching the Corrective Mass

- Install the correction weight on the rotor according to the software's calculations.

- Periodic checks can be performed to ensure the balancing procedure is effectively reducing the vibration.

Validation and Conclusion of the Balancing Process

- With the compensating weight attached, operate the rotor and assess the level of any residual vibration.

- If the vibration level is within acceptable limits (according to ISO 1940), the balancing is complete.

- Should the vibration still be excessive, repeat the balancing steps, making further adjustments to the corrective weight as needed.

Report Generation

- All balancing results are logged and archived within the software, from which you can produce a printable report summarizing the vibration levels, compensating weight, and its installation position.

Final Recommendations

- Verify the secure attachment of all balancing weights and measurement sensors.

- Check that the rotor's rotation is smooth and free from undue noise or vibration.

- In cases where the rotor is integrated into a more complex system, ensure the correct operation and interaction of all related components.

This process allows for precise imbalance correction, reducing vibration and extending equipment life.

Instagram: https://www.instagram.com/vibromera_ou/ Youtube : https://youtu.be/guA6XJ-ArZM?si=vmkuX7RILzKBl0zL Our website about Balancing of refrigeration compressors Machinio: https://www.machinio.com/listings/98380186-portable-balancer-vibration-analyzer-balanset-1a-full-kit-in-portugal Facebook: https://www.facebook.com/marketplace/item/350151228150722