Internet Explorer

Internet Explorer is not supported. Please upgrade to a more modern browser.

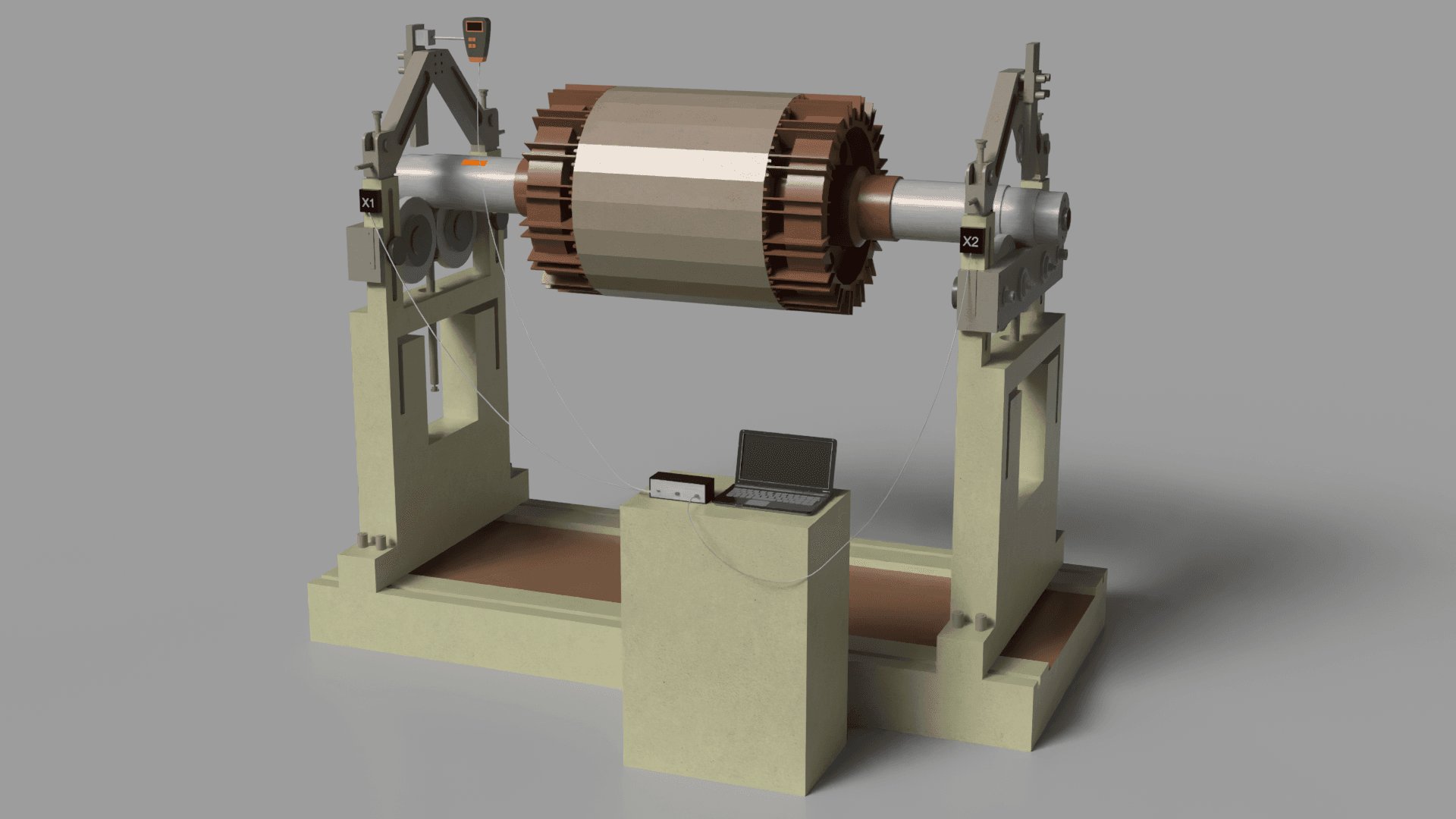

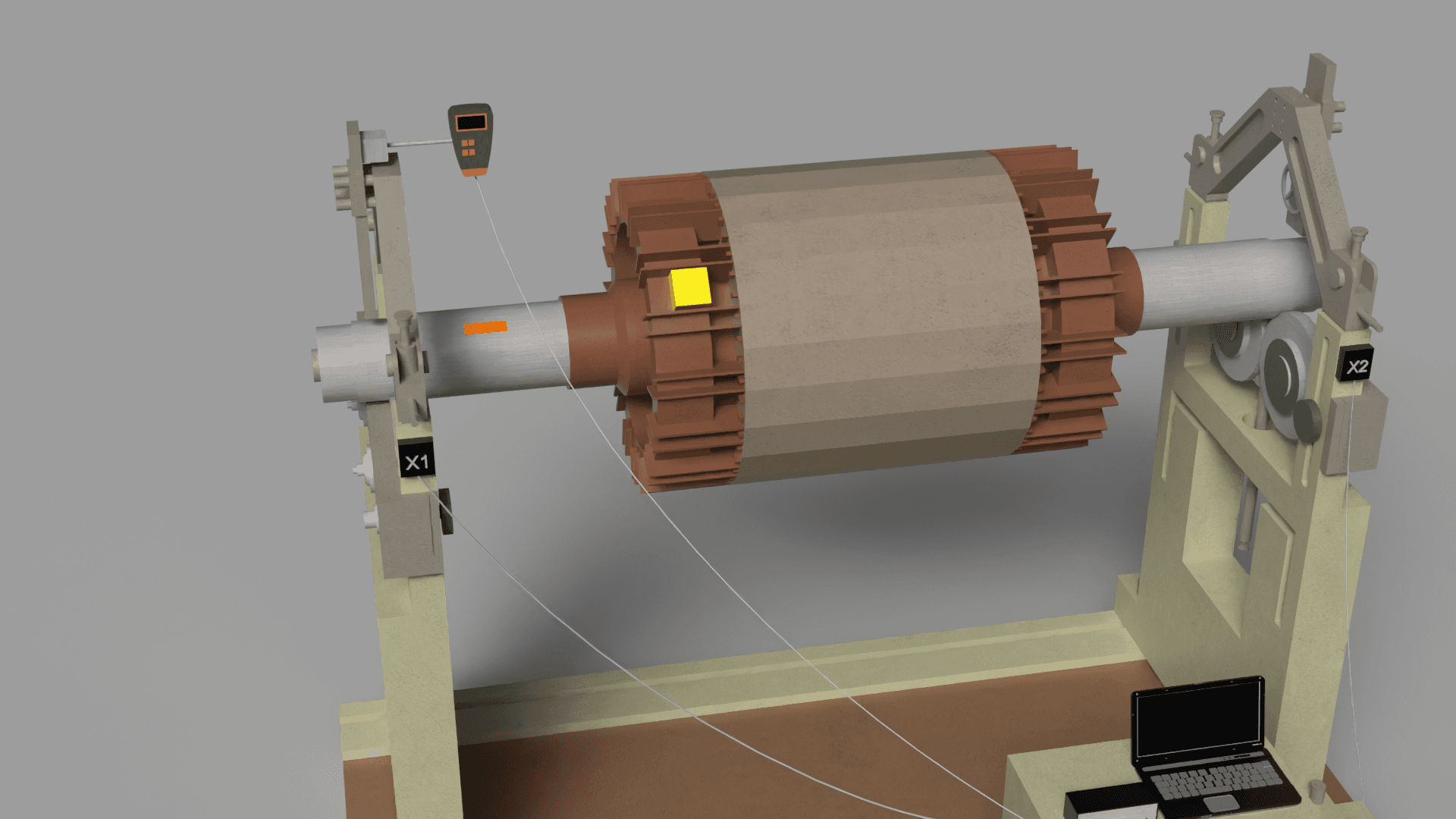

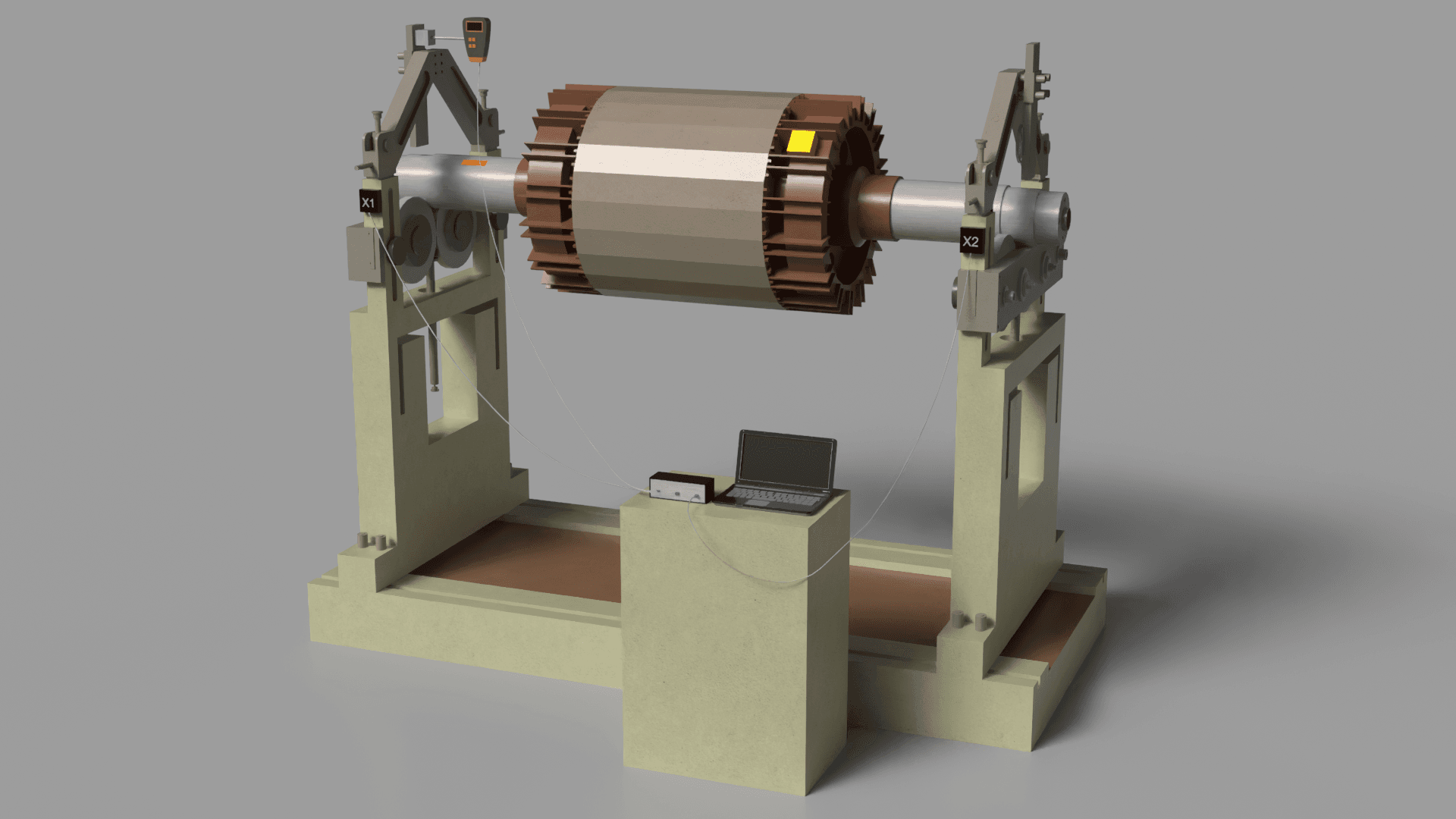

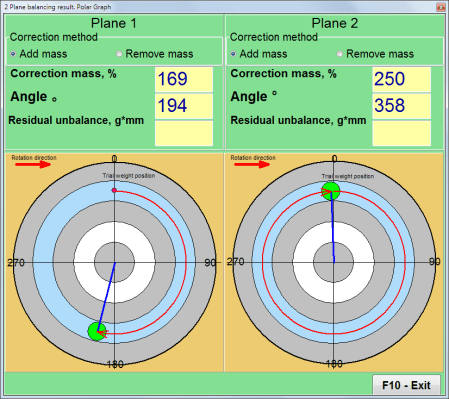

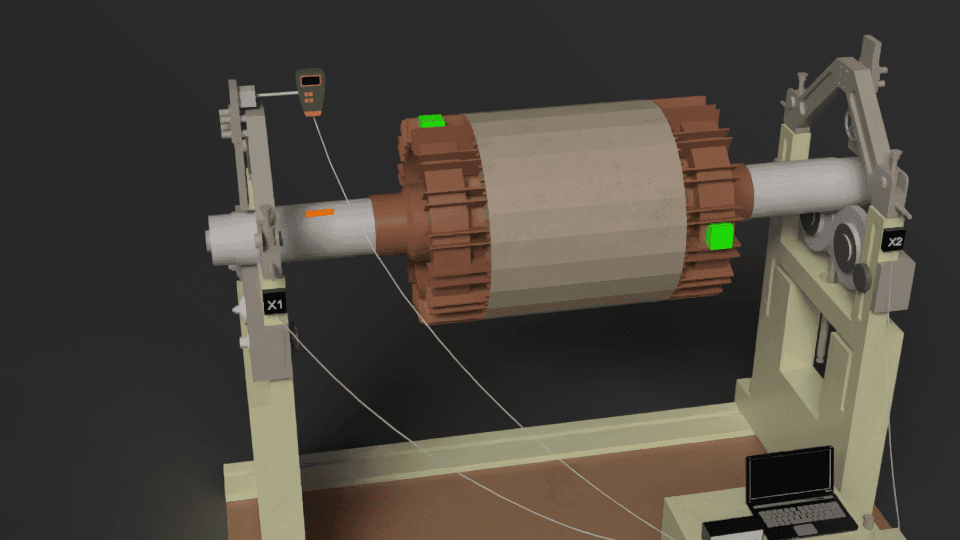

This process allows for precise imbalance correction, reducing vibration and extending equipment life.

Instagram: https://www.instagram.com/vibromera_ou/ Youtube : https://youtu.be/guA6XJ-ArZM?si=vmkuX7RILzKBl0zL Our website about Balancing of refrigeration compressors Machinio: https://www.machinio.com/listings/98380186-portable-balancer-vibration-analyzer-balanset-1a-full-kit-in-portugal Facebook: https://www.facebook.com/marketplace/item/350151228150722